Container Homes: A Modern Living Option Worth Exploring

Shipping container homes provide a practical and innovative option for modern living. This article outlines how these homes are constructed, what to consider before choosing this style of housing, and key factors like design, permits, and potential cost benefits. It’s a helpful overview for anyone exploring alternative housing options.

What Are the Benefits of Shipping Container Homes?

Shipping container homes offer several compelling advantages over conventional housing options. First and foremost is their sustainability factor. Repurposing shipping containers gives new life to structures that might otherwise sit unused in ports worldwide. Each recycled container prevents approximately 3,500 kg of steel from being melted down, significantly reducing the carbon footprint associated with new construction materials.

Durability stands as another major benefit. Designed to withstand ocean transport, these containers are built from weather-resistant Corten steel that can endure extreme conditions including hurricanes, earthquakes, and fires when properly reinforced. Their modular nature also allows for remarkable construction speed—a basic container home can be assembled in weeks rather than the months typically required for standard construction.

Additionally, container homes offer excellent mobility options. Though not as easily transported as RVs, they can be relocated with proper planning and equipment, providing flexibility for homeowners who may need to move in the future. Their compact design also makes them ideal for challenging building sites where conventional construction might prove difficult or impossible.

How Do Design & Customization Ideas Transform Container Spaces?

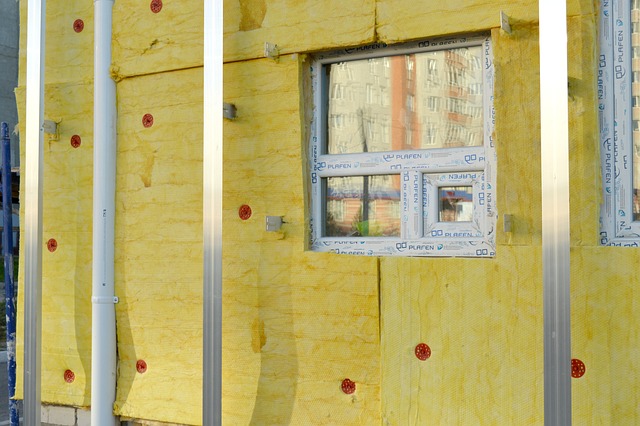

The rectangular confines of shipping containers present both challenges and creative opportunities for home designers. Modern architectural approaches have transformed these utilitarian boxes into stunning living spaces through thoughtful design interventions. Common customization techniques include cutting out sections for windows and doors, installing insulation systems, and adding exterior cladding that can completely transform the industrial appearance.

Interior design for container homes focuses on maximizing limited square footage through multi-functional furniture, strategic storage solutions, and open-concept layouts. Floor-to-ceiling windows and glass doors are frequently incorporated to create a sense of spaciousness and connection with the outdoors. Some designers utilize multiple containers placed at angles or stacked to create more complex, spacious structures with interesting architectural features.

Customization options extend to roofing solutions as well, with green roofs becoming increasingly popular for their insulation properties and environmental benefits. Other homeowners opt for rooftop decks or solar panel installations that make use of the typically flat container surfaces. These modifications not only enhance the aesthetic appeal but can also improve energy efficiency and functionality.

What Does the Step-by-Step Building Process Involve?

Creating a container home begins with careful planning and design. This initial phase includes selecting appropriate containers (new or used), determining the layout, and creating architectural plans that address structural modifications. During this stage, obtaining necessary building permits is essential, as code requirements for container homes vary significantly by location.

The foundation preparation represents a critical step in the process. Options range from traditional concrete slabs to pier foundations that minimize environmental impact. Once the foundation is ready, the containers are delivered to the site and placed according to the architectural plans, typically using a crane. Structural reinforcements must be added wherever the container walls will be cut for windows, doors, or to connect multiple units.

After the basic structure is in place, the construction process shifts to insulation installation—a crucial component in making container homes comfortable and energy-efficient. Several methods exist, including spray foam, rigid panel insulation, or natural alternatives like wool or cotton. Following insulation, interior finishing work proceeds much like traditional construction: installing plumbing, electrical systems, drywall or alternative wall coverings, flooring, and fixtures. The entire process, from design to completion, typically takes 2-6 months depending on complexity.

How Does Cost Comparison vs. Traditional Housing Stack Up?

When comparing costs between shipping container homes and traditional construction, several factors must be considered. Container homes often offer significant savings in materials and labor costs, with basic single-container dwellings starting at approximately $30,000 for DIY builders. More elaborate multi-container designs with high-end finishes can range from $100,000 to $250,000, still potentially lower than comparable conventional homes in many markets.

The most substantial savings typically come from reduced construction time, lower material costs, and potential labor savings. However, these advantages can be partially offset by specialized expenses unique to container homes, including transportation of containers to the building site, crane rental for placement, and specialized cutting and welding work.

| Housing Type | Average Cost per Square Foot | Average Time to Complete | Typical Lifespan |

|---|---|---|---|

| Basic Container Home | $100-150 | 2-3 months | 25+ years with maintenance |

| Luxury Container Home | $200-300 | 4-6 months | 25+ years with maintenance |

| Traditional Stick-Built Home | $150-250 | 7-12 months | 30-100 years |

| Modular Home | $120-200 | 3-4 months | 30-55 years |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

What Financing & ROI of Container Homes Should You Consider?

Financing a container home presents unique challenges compared to traditional housing. Many conventional mortgage lenders remain hesitant about container structures, often classifying them as alternative housing. However, as their popularity grows, more financial institutions have begun offering specialized loans for these projects. For those unable to secure traditional financing, personal loans, construction loans, or manufacturer financing represent viable alternatives.

When evaluating the return on investment (ROI) potential, several factors merit consideration. While container homes may appreciate more slowly than traditional houses in some markets, their lower initial cost can mean less financial risk. Energy efficiency represents another economic benefit—with proper insulation and modern systems, container homes can significantly reduce utility costs compared to conventional housing of similar size.

The resale market for container homes continues to evolve. While some regions show strong demand for these unique properties, others may present challenges when selling. Factors influencing resale value include quality of construction, design aesthetics, compliance with local building codes, and overall market acceptance of alternative housing in the area. For optimal ROI, focusing on high-quality finishes, energy efficiency, and architectural design that minimizes the industrial appearance can prove beneficial.

Conclusion

Shipping container homes represent an innovative approach to housing that balances sustainability, efficiency, and creative design. While they present certain challenges related to building codes, financing, and climate adaptation, their benefits make them an increasingly attractive alternative to traditional construction. Whether as a primary residence, vacation home, or rental property, container homes offer a unique opportunity to redefine modern living spaces while potentially reducing both environmental impact and housing costs.